25 Years of Innovation Blue Wave Advances CVD Diamond Solutions for Emerging Technologies, located in Baltimore, MD, USA

Blue Wave Semiconductors has expanded its CVD diamond coating product line & capabilities at Baltimore, Maryland, USA, based on 25 years of expertise.

BALTIMORE, MD, UNITED STATES, June 10, 2025 /EINPresswire.com/ -- Blue Wave Semiconductors has expanded its Chemical Vapor Deposition (CVD) diamond coating product line and capabilities at its foundry in Baltimore, Maryland, USA, building on 25 years of expertise in the field. CVD diamond is widely used in advanced industrial components due to its exceptional mechanical hardness, high thermal conductivity, chemical inertness, wide bandgap, and radiation resistance.Known for its long-standing reputation in coating services, Blue Wave specializes in CVD diamond coatings of various grades on advanced technology substrates such as silicon, silicon carbide (SiC), molybdenum (Moly), and proprietary materials. The company has recently enhanced its fabrication capabilities to support custom sizes and shapes of CVD diamond coatings.

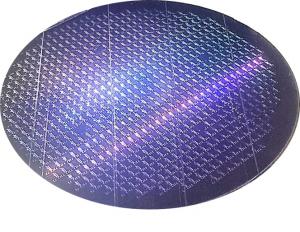

“Every customer is valuable,” said Dr. R.D. Vispute, CTO of Blue Wave Semiconductors. “To meet their diverse needs, we’ve expanded our coating systems to support everything from R&D-scale applications to full production, including large-area coatings up to 8-inch diameter silicon wafers.”

Blue Wave Semiconductors possesses proprietary processes for growing single-crystal to polycrystalline and fine-grained CVD diamond coatings. These are used in a wide range of applications, including quantum sensors and detectors, radiation-hardened electronics, thermal management wafers for microelectronics, ultra-thin film foils and membranes for high-energy applications, doped diamond for electronic device control, and MEMS-related mechanical coatings.

Over the past 25 years, the company has developed a suite of CVD diamond systems, including small-area hot filament CVD, large-area hot filament CVD Diamond systems, and the DEAR MPCVD Diamond system for single-crystal growth.

Customized CVD diamond systems tailored to client specifications are also available.

“CVD diamond is a high-tech material, and demand for systems that meet specific customer requirements is increasing,” noted Dr. Vispute. Blue Wave also collaborates with R&D groups at top-tier research universities and national laboratories.

In addition to expanding its growth facilities, Blue Wave has introduced advanced characterization capabilities. These include quantum-level coating analysis, electrical and photonic measurements, photoluminescence and cathodoluminescence down to 77K, UV-visible spectroscopy, optical emission spectroscopy during growth, laser interference spectroscopy, Raman spectroscopy, and device-level electrical characterization.

Blue Wave’s CVD diamond systems offer a variety of diamond qualities, optimized for different applications. The company’s foundry includes HFCVD and DEAR MPCVD systems with in-situ monitoring, remote control, and fully automated processes that can be initiated with a single click. These systems are designed for full automation and integration with machine learning and artificial intelligence, as well as compatibility with physical vapor deposition (PVD) tools such as pulsed laser deposition, electron beam evaporation, reactive sputtering, thermal evaporation, and other CVD techniques used in next-generation semiconductor fabrication.

Blue Wave Semiconductors is actively developing advanced high-tech products utilizing CVD diamond, ranging from specialized components to transformative technologies. With its strong foundation in substrate heating, CVD processes, vacuum technology, materials science, and thin film R&D, Blue Wave is strategically positioned to develop thermal, optical, and electronic products with significant defense and industrial potential. The integration of CVD diamond with both conventional and emerging semiconductor materials remains one of the company’s core strengths.

About Blue Wave Semiconductors:

Blue Wave Semiconductors is a pioneering company specializing in the development of advanced materials and cutting-edge technologies for next-generation applications, including quantum sensing, electronics, and composite materials. The company is a graduate of bwtech@UMBC, a leading technology incubator affiliated with the University of Maryland, Baltimore County (UMBC). bwtech@UMBC provides startups and growing companies with access to state-of-the-art facilities, mentorship, and entrepreneurial resources, fostering innovation and commercialization in cutting-edge technologies. As part of the bwtech and Maryland ecosystem, Blue Wave Semiconductors has leveraged the Maryland M4 grant to develop groundbreaking solutions like the DEAR MPCVD system. To learn more about the CVD diamond capabilities of Blue Wave Semiconductors’ innovative research, visit www.bluewavesemi.com.

Ratnakar D Vispute

Blue Wave Semiconductors, INC.

email us here

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

Distribution channels: Technology

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release